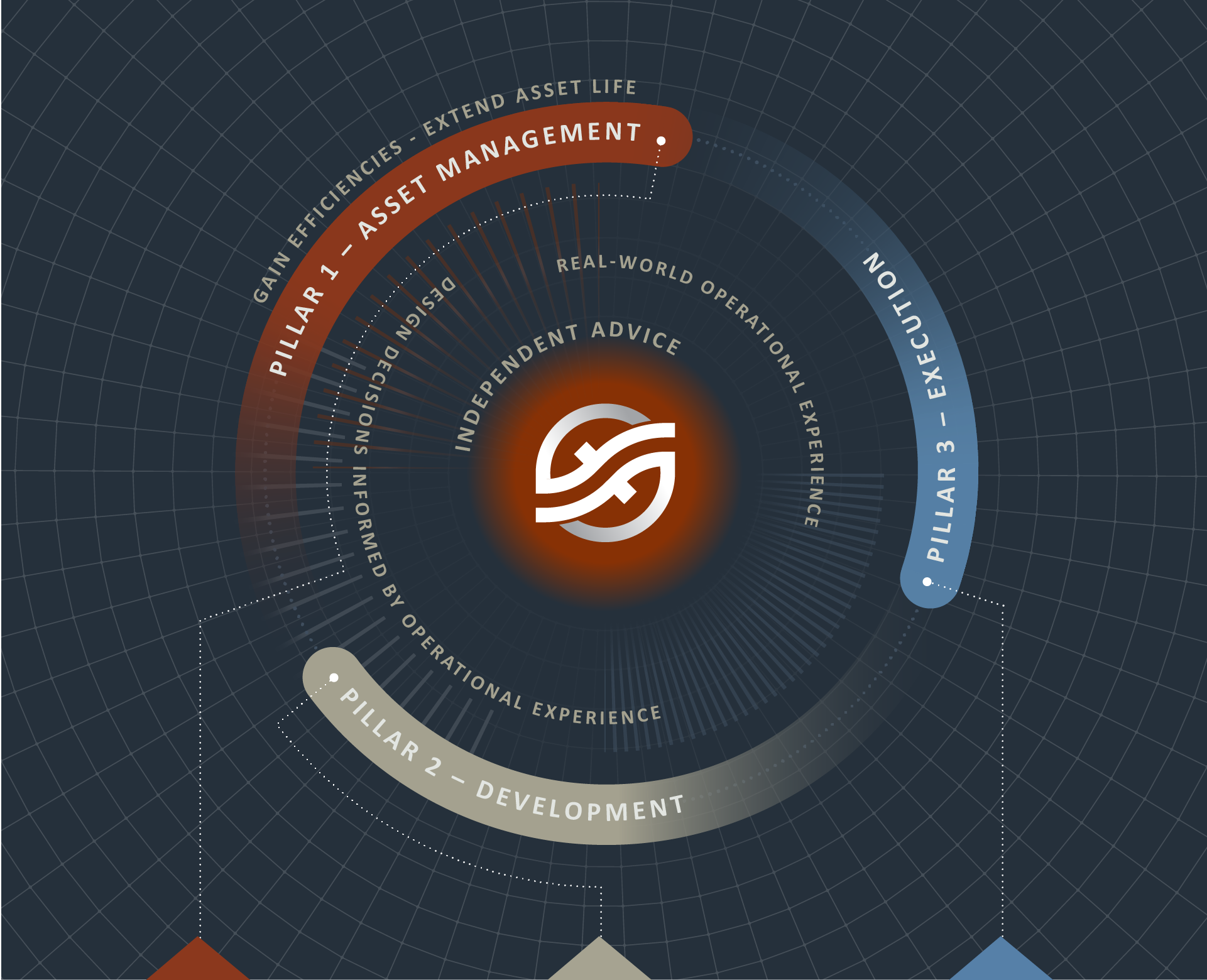

Our service offering comprises 3 service pillars, the order of which may appear counter to traditional thinking. We always start with the end in mind, so in everything we do we have the long term efficient operation and management of the slurry pipeline asset at the forefront of our process. Founded on the solid base of experience in asset management, the other pillars are built, including operation and constructability informed design, and efficient project development.

PILLAR 1

ASSET MANAGEMENT

Start with the end in mind

Operator training and a detailed understanding of the safe operating limits of the slurry pipeline system provides the foundation of an effective slurry pipeline integrity management plan. We develop tailored operator training modules to support owners/operator retaining and growing their operational knowledge whilst also continuously incorporating industry best practice.

We believe an evolving operating training program enables operating knowledge to be retained and improved therefore reducing risk for the life of the asset.

Pipelines are designed to specific process conditions whilst the properties of the ore body and mining operation are inherently changing over the life of the asset. Understanding of the potential impact of changing processes but also operational practices over the life of the pipeline asset is critical in assessing its present and future performance. It also provides a better understanding of risks and potential new controls required to ensure longevity of the asset. Operational Performance audits provide an assessment of key performance indicators and help identify potential new risks and controls for the operation

Pipeline integrity comprises inspection and assessment. We support owners and operators in the assessment of inspection data and the determination of potential present and future integrity risks to the pipeline system.

Pipeline integrity assessments relate to current operating conditions and integrity risks, however the requirement to forecast potential future integrity risks requires a deep understanding of past and potential future operating parameters.

We provide integrity assessment and planning services to support risk identification and the implementation of a measurable risk mitigation action plan.

Pipeline internal wear is a function of erosion and corrosion. For long distance slurry pipelines, erosion has been found to be a function of particle diameter, operating velocity, pipe diameter and slurry concentration (Kawasima et al). The corrosion component has been found to be associated with chemical and microbiological composition of the slurry.

We have developed industry partnerships with fellow subject matter experts and instrumentation suppliers to support the continuous improvement in the field of predictive wear modelling.

We provide wear assessment services for existing and future pipeline assets.

Pipeline root cause failure analysis is an important input to any mature pipeline integrity plan. It provides the necessary insight and data to help quantify future integrity risks as well as identifying necessary new controls.

We partner with industry specialists and subject matter experts including quality assessment, chemical analysis, destructive testing, and assessment of operational practices to support an hypothesis and fact based RCFA.

PILLAR 2

DESIGN

Proven technology

Project conceptualization services are aimed at assessing the technical and commercial viability of a pipeline option using desktop route selection combined with basic pipeline hydraulic modelling using a minimum of input and benchmarked against other similar pipeline projects.

Project feasibility activities are primarily aimed at improving the quality of the design input and therefore confidence level of the system selection and estimate. This includes preliminary field route selection, advanced slurry characterization test work and hydraulic modelling, budgetary estimates for major equipment and materials, crew based pipeline construction estimate and contingency analysis. Project definition is also improved via preliminary operating philosophy and supporting process drawings as well as a preliminary project execution plan and schedule.

Bankable feasibility engineering services are aimed at meeting budgeting and financing requirements. This includes both technical and commercial feasibility. Technical feasibility is benchmarked against other similar commercial operations. Commercial feasibility is substantiated by improved route constraint analysis as well as construction input data to support a detailed pipeline and station construction estimate. A detailed project execution plan and schedule is provided.

Preliminary design (basic design) services are aimed at substantiating an overall 80% technical and commercial confidence level and potentially supporting the early phases of the procurement process including tendering of the construction and major equipment packages.

Detailed design services are aimed at substantiating an overall 90% technical and commercial confidence level and potentially supporting all procurement and execution activities.

PILLAR 3

EXECUTION

Certainty of outcome

We support owners and contractors developing sound contracting strategies, providing insight on reputable contractors, equipment suppliers, approvals processes and potential partners to better inform project execution planning and logistics.

We provide advisory engineering services and insights derived from full project lifecycle involvement, specifically design involvement with more than 20 commercial pipeline operations globally, pipeline commissioning and operation, operational performance and integrity management audits.

We also provide an owners perspective gained from our involvement in the design management, procurement and construction support of a major slurry and water pipeline project in Western Australia.

Procurement support services include identifying procurement strategy and suppliers, procurement technical and commercial evaluation, quality assessment and control.